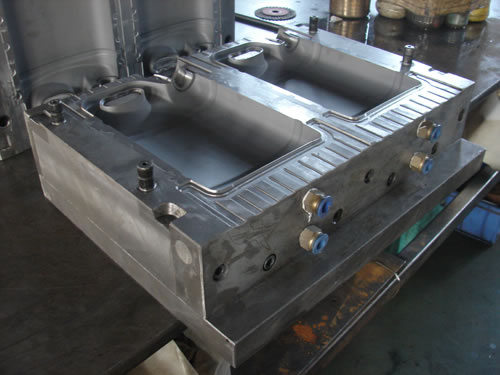

Cleaning Stuff Bottle Mold

Description

The plastic bottle molds are made by multi-cavity such as 2-cavity, 4- cavity and 6-cavity in accordance with the volume of bottle. Our PET bottle molds are designed by experienced engineer in compliance with international standards and norms. We offer various cleaning stuff bottle mold, such as toilet cleaner bottle mold, detergent bottle mold and shampoo bottle mold. For the safe delivery of these plastic bottle molds, we guarantee to undertake effective packaging to keep their shape intact.

Features of Cleaning Stuff Bottle Mold

1.The PET bottle molds use excellent stainless steel to guarantee the top quality and long life

2.The entire precise mold are made by numerical CNC machine in order to ensure end product is without rough edges

3.The plastic bottle molds feature in durability, reliability, low maintenance, corrosion resistance and robust construction

4.Our PET bottle mold adopts circulating water treatment system to shorten the cooling time and improve the production efficiency

5.We provide precise mold sample for our customers

Maintenance

1.The plastic bottle molds should be better maintained, so the service life can be longer than before

2.The moving parts such as thimble, guide pillar and guide sleeve should be lubricated at regular time

3.The surface of shampoo bottle mold must be cleaned. All of the parts should be maintained every day when producing the moulds

4.The users may clean the vent groove and repair the damaged and worn parts at scheduled time

5.For appearance maintenance, the outside of the blow molding machine should be painted in order to avoid rust

5.The PET bottle mold machine must be closed tightly to prevent the dust into the cavity

Technical Requirements

1.We analyze the forming process, mold structure and fabricating technique in order to ensure the service life of the plastic bottle molds can reach more than one million times

2.The mould structure and machining parts must be completely designed. The requirements of installation and injection molding process should be proposed

3.The appearance of the plastic bottle molds must make sure no rust, no crushing abrasion and mould defects

4.The reference book for the quick-wear parts and maintenance of this PET bottle mold must be provided

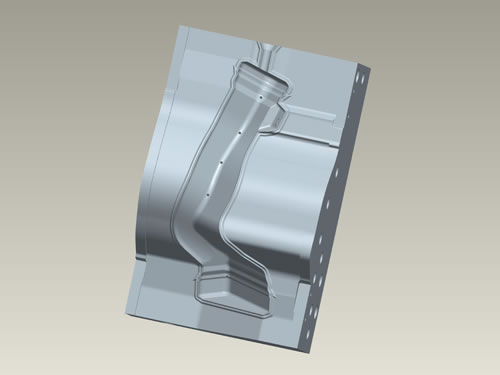

Lanteky® Machine is specialized manufacturer and supplier of precise mold in China. With strong R&D capability, we design and manufacture cleaning stuff bottle mold and shampoo bottle mold. We use multi-axis CNC equipment for machining our plastic bottle mold and adopt semi-automatic production lines so as to enhance work efficiency. For PET bottle mold machine design, we obey the principle of simple design in order to save production costs. We have introduced Germanic technical 3D scanner used for designing our shampoo bottle mold.

- Auto Parts MoldThis kind of precise mold can be divided into various types, such as bumper mold, control panel mould, shock absorber mold, inner trim mould and automotive lighting system mold. The automotive parts mold is the general name for all the moulds which makes different car parts. There are stamping die, injection mold, forging mould and glass mold...