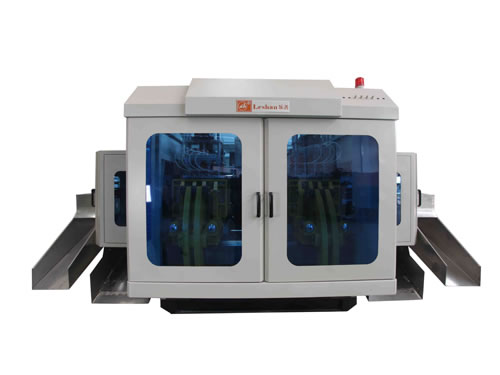

- 85U2X8.5G Extrusion Blow Molding MachineExtrusion blowing machine applies to manufacture the hollow plastic products under 0.5L ...

- 75U2X1.10F Extrusion Blow Molding Machine75U2X1.10F extrusion blow moulding machines are designed to produce various kinds of containers...

- 65U2X6.2G Automatic Blow Molding Machine65U2X6.2G automatic blow molding equipment with high production output can be used for producing ...

- 65U2X1.5F Bottle Blow Molding Machine65U2X1.5F bottle making machine is designed for production of 4L lubrication bottle, 4L cleaning ...

Extrusion blow molding machine applies to manufacture the hollow plastic products under 0.5L of PE, PP, EVA, ABS, PVC, K, TPU, Nylon and other materials. It is suitable for production of milk bottle, glue bottle and drug bottle. The bottle blowing machine also can be used for dairy, food, beverage, medical, cosmetic, personal care, lubrication oil containers, chemical and industrial applications.

- 75K2X6.5D-A Extrusion Blow Molding Machine1.This type has six die head, double station and single layer with high production output ...

- 75K2X1.10D Extrusion Blow Molding Machine1.This equipment owns single die head, double station and single layer extrusion. It also can be equipped ...

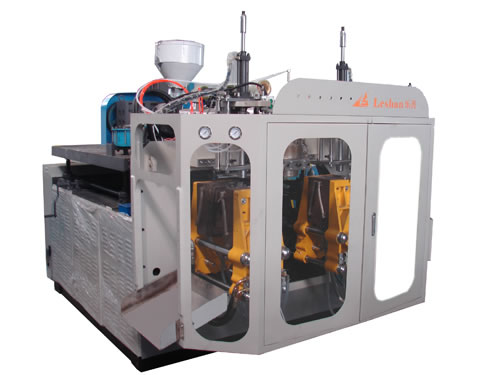

- 65K2X1.5D Automatic Blow Molding Machine1.65K2X1.5D automatic blowing machine adopts single die head, double station and single layer extrusion...

- 55K2X1.2D Bottle Blow Molding Machine1. 55K2X1.2D type is configured with single die head, double station and single layer extrusion ...

- 45K2X1.2D Plastic Blow Molding Machine1. This machinery owns single die head, double station and single layer

2. 45K2X1.2D plastic bottle ...

K series blow molding machine is used for the production of hollow plastic products under 10L of PE, PP, EVA, ABS, PVC, K material, TPU, BARES, Nylon and other materials. The main difference between U series is that this machine adopts tie bar clamping system. They are easy to manipulate and fix up. Passion control system and auto-deflasher system also can be mounted on K series blow molding equipment. The main features of this blowing machine are low energy consumption, raw material-saving, labor-saving and high production rate.

- 55Y2x2.05D Automatic Blow Molding MachinePETG blowing machine can blow the pesticide bottle, cosmetics bottle, wide-mouth bottle, hot filling ...

- 45YG2x1.1C Automatic Blow Molding Machine45YG2x1.1C automatic bottle blowing machine adopt three tie bar hydraulic horizontal formwork ...

YG series blowing machines are specially designed for PETG and PVC products. This machine possesses three tie bar horizontal station, high rigidity PVC screw controlled by inverter and PVC die head. In addition, this series automatic stretch blow molding machine adopts YUKEN oil valve, high-tech oil pump and Rexroth electromagnetic reversing valve. YG series bottle molding machines are available to create small and medium size bottles as well as 30 ml to 2-liter containers.

- 85Y1x1.25D Blow Molding Machine1.Single station matching with die head can avoid forming the explosive and fissile convergence line...

- 90Y1x1.30D Giant Bottle Blow Molding MachineThis large-size bottle molding machine is mainly used for the production of plastic hollow ...

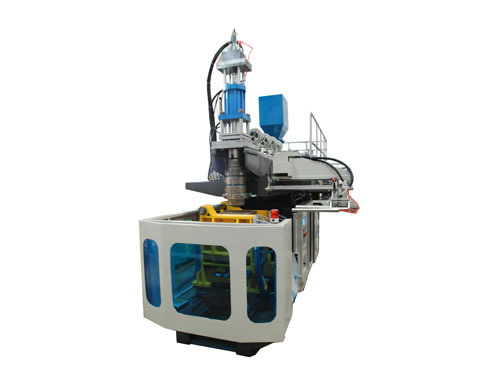

- 90K+H2x1.30D Giant Plastic Blow Molding Machine90K+H2x1.30D large-scale plastic blowing machines are developed on the base of K series blow molding...

- 100U2x1.30F Automatic Blow Molding Machine100U2x1.30F fully automatic blowing machine is used for the manufacture of various packing ...

- 100H1x1.100D Extrusion Blow Molding MachineThe injection blow moulding machines are mainly suitable for the production of various large and medium-sized ...

The large-scale blow molding machine is designed to produce various packing barrels with PE and PP material and the capacity from 10l to 160L, including toolbox, motorcar parts such as gasoline tank, wind pipe and other large and medium-sized plastic hollow products.

The large bottle blowing machine adopts new patent of two pull-rod type closing-mold device for the purpose of completely achieving full automatic production. The large-scale blow molding machine uses fully computer controlled electronic system, which has the functions of technical parameter optimization and self-diagnosis.

- EPET06-4H Stretch Blow Molding MachineEPET06-4H stretch blowing machine is designed to produce the containers for food ...

- EPET06-6H Automatic Blow Molding MachineEPET06-6H automatic blow moulding machine can make different kinds of bottles in shapes, including ...

PET bottle blowing equipment is one of the most stable two-step automatic stretch blow moulding machine. This all-electric PET stretch blow molding machine can be applied in the bottle production of carbonated drinks, mineral water, pesticide bottle, cosmetics, wide-mouth, hot filling and other packing containers with PET and PP materials.

Blow Molding Machine

Description

Blow molding machine is designed to make the hollow plastic parts into plastic bottles through a certain technology process. The blow molding equipment is suitable for the production of plastic containers with PE, PP, PC, PS and PVC as raw material and the capacity ranging from 1ml to 100L. Our blow molding machine can be used in beverage packaging, medicine bottle container, lubrication bottle, cleaning supplies container, large-scale drums, toolboxes, mailboxes and air pipe.

Features

1.This machine is applicable to the production of plastic bottles

2.The blowing machine has various advantages including stable operation, high quality, high efficiency as well as low energy consumption

3.The average energy consumption of this blow molding machine is lower than the market average of 10%-15%.

Blow Molding Process

There are three types of blow molding including extrusion blow molding, injection blow molding and stretch blow molding. The blow molding process starts with melting down the plastic and forming it into a parison or preform. In order to keep the shape of the bottle, the plastic shall be cooled. There is a hole in one end of the tube-like parison which allows compressed air to pass through. Then we put the parison into a mold and pump the high pressure air into it so as to blow the parison plastic bottles.

Lanteky® Machine is a professional manufacturer and supplier of blow molding machine in China. We offer all-electric PET blow molding equipment, auxiliary machine of blow molding and high precise mould for customers to select. Till now, we have obtained the CE certificate for U series blowing machine. We also have owed 5 patents for invention and 26 patents for utility models. If you need our blow molding equipment, please contact us.