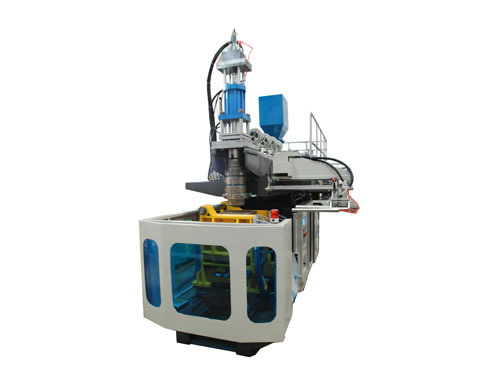

90Y1x1.30D Giant Bottle Blow Molding Machine

Description

This large-size bottle blow molding machine is mainly used for the production of plastic hollow products under 30 liters with PE, PP, ABS and PC materials, including pot, blow molding barrel, five gallons of pure buckets, cans, bags, tubes, hollow board, box, ball and air pipe.

Features of Large-size Bottle Blow Molding Machine

1.This super size blowing machine has a high mechanical base, there is no need to dig holes for installing the standard multi-function below blow throwing devices

2.The maximum blow volume is 30L. PE, PP, PS, PC and PVC can be used

3.The large-size bottle blow molding machine is applicable for production of chemical barrels, auto parts and sprayer and so on

4.The screw diameter is 90mm

5.The super size blowing machine adopts program plus modules to control temperature

6.Adopting new platform type die head design, this large-size bottle blow molding machine can separate the lifting platform from head-rising platform, which not only makes the rise of the die head more stable, but also allows the die head to move forwards and backwards

7.Strong clamping force with high pressure and double crank links to lock the mold

8.This super size blowing machine can be operated automatically or manually

9.The bottle making machine can decrease the power consumption due to double pump and proportional flow valve

10. The die head piston and material storage cavity adopt very hard wear-resistant materials, offering durable service life

11. This large-size bottle blow molding machine can be configured with automatic hydraulic lift system and telemaintenance system

12. The accumulator is equipped with electronic feet for controlling and tracking, and it is more precise than the sensor and easier to control

13. The hardening and tempering guide pillar with high-precision linear guide way offers little friction and wear resistance

14. The super size blowing machine can employ automatic ejection procedures and oil channels for the purpose of adding plus demoulding device conveniently

15. The large-size bottle blow molding machine uses automatic lubrication system for scheduled maintenance

16.The super size blowing machine adopts light curtain safety protection system to ensure the personal safety of operating personnel

17.Advanced technology is used to manufacture components, and the components have high precision and high quality

Components of Large-scale Bottle Blow Molding Machine

1.This automatic bottle blow molding machine can be configured with accumulator, 50/100 points parison control, down blow pin, down widen device, double clamping and robot hand.

2.The large-size bottle blow molding machine utilizes advanced technology to process the elements, and the elements have high precision and high quality

Parameters of Automatic Bottle Blow Molding Machine

| Model | 90Y+H1x1.30D | |

| Max Volume Blown | (L) | 30 |

| Applied Material | / | PE |

| No. of Die Head | / | 1 |

| Central Distance | (mm) | 4.5 |

| No. of Stantion | / | 1 |

| Screw Dia | (mm) | 90 |

| L/D Ratio | / | 23 |

| Screw Rotating Speed | (rpm) | 20-65 |

| Max Plasticizing Capacity | (kg/h) | 160 |

| Extruding Motor Power | (kW) | 37 |

| Oil Pump Motor Power | (kW) | 15 |

| Barrel Zone | / | 4 |

| Barrel Heating Power | (kW) | 17.5 |

| Head Heating Zone | / | 3 |

| Head Heating Power | (kW) | 16 |

| Total Power | (kW) | 85.5 |

| Dimension of Mould Plate | (mm) | 720x650 (520x900) |

| Min Clamping Distance of Mold | (mm) | 280 |

| Mold Stroke | (mm) | 450 |

| Max Size of Mold | (mm,W×H) | 900 |

| Clamping Force | (kN) | 450 |

| Net Weight | (kg) | 9250 |

| Dimension of Machine | (m, L×H×W) | 4.9x3.5x2.83 |

| Pressure of Hydraulic System | Mpa | 14 |

| Pressure of Pneumatic System | Mpa | 0.6-0.8 |

| Pressure of Cooling System | Mpa | 0.2-0.3 |

| Air Consumption | m3/hr | 5 |

Maintenance

One year warranty is offered for our large-size bottle blow molding machine. We can provide free installation for domestic market, chargeable debugging in oversea market. The equipment parts are free replacement for one year except for the easily damaged parts.

Note

Stable blowing air, low temperature cooling water and continuous electricity supply are required when using this super size blowing machine

Packaging and Transportation

The large-size bottle blow molding machine will be packed with film seal

Lanteky® Machine is a professional super size blowing machine manufacturer and supplier in China. With registered capital of ten million and one RMB, we offer blow molding machine, automatic blow molding machinery, auxiliary machine of blow molding, bottle making machine and high precise mould. Our products like large-size bottle blow molding machines are not only sold well in domestic markets, but also exported to Malaysia, Indonesia, Nigeria Mexico, Egypt, Dubai, Algeria, Australia, New Zealand, Chile, Mali, Russia, Philippians, Singapore, Vietnam, India and Costa Rica.

- 90K+H2x1.30D Giant Plastic Blow Molding Machine90K+H2x1.30D large-scale plastic blow molding machines are developed on the base of K series blow molding machines. This large-size bottle blow molding machine combines the advantages of tie bar clamping system and independent platform from K series and Y series blow molding machines.

1.This super size blowing machine adopts new patent of two pull-rod type closing-mold device...