- U Series Blow Molding MachineExtrusion blow moulding machine applies to manufacture the hollow plastic products under 0.5L of PE, PP, EVA, ABS, PVC, K, TPU, Nylon and other ...

- K Series Blow Molding MachineK series blow molding equipment is used for the production of hollow plastic products under 10L of PE, PP, EVA, ABS, PVC, K material, TPU, BARES ...

- YG Series Blow Molding MachineYG series bottle molding machines are specially designed for PETG and PVC products. This machine possesses three tie bar horizontal station...

- Giant Blow Molding MachineThe large-scale blow moulding machine is designed to produce various packing barrels with PE and PP material and the capacity from 10L to 160L...

- PET Series Blow Molding MachinePET blowing machine is one of the most stable two-step automatic stretch blow moulding machine. This all-electric PET stretch blow molding machine...

Blow molding machine is designed to make the hollow plastic parts into plastic bottles through a certain technology process. The blow moulding machine or equipment is suitable for the production of plastic containers with PE, PP, PC, PS and PVC as raw material and the capacity ranging from 1ml to 100L. Our blow molding machine can be used in beverage packaging, medicine bottle container, lubrication bottle, cleaning supplies container, large-scale drums, toolboxes, mailboxes and air pipe.

- Auto-Feeder UnitThe auto-feeder unit is designed for the production of plastic products in injection molding workshop. This auxiliary equipment can accomplish ongoing ...

- Labeling UnitAutomatic labeling machine is used to paste the paper or metal foil label on the packaging containers. It can achieve planar labeling, single ...

- Leak Testing UnitThe leak testing machine is designed and manufactured to identify whether the containers are leakage. This auxiliary equipment eliminates ...

- Conveyor UnitA conveyor unit is a kind of mechanical handling equipment that transports materials from one location to another. This auxiliary equipment has many ...

- 4 In1 Crushing UnitThis 4 in1 crushing unit is a combination of crusher, mixer, conveyer and distributor. Plastic crushing machine is used to smash the waste plastics...

- Cooling MachineCooling machine achieves the refrigeration effect through steam compression or absorption cycle. The liquid can flow through the heat ...

Auxiliary machine is a set of accessory equipment and peripherals for blow molding. Our auxiliary equipment for blow molding machine includes central feeding system, automatic labeling machine, leak testing machine, conveyor unit, 4 In1 crushing unit and cooling machine. Leshan is glad to provide auxiliary machine for our blow molding machines.

The auxiliary equipment is broadly used in national defense, electromechanical, automobile, transportation, packaging, agriculture...

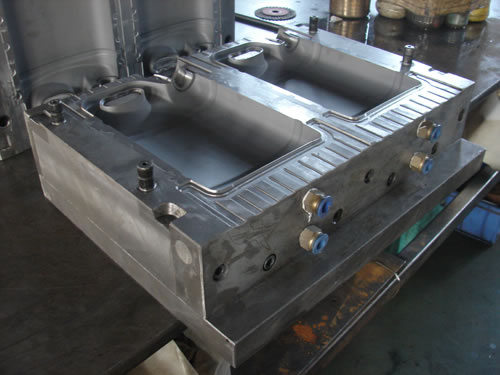

- Milk Bottle MoldThe milk bottle mold can be made of magnalium and stainless steel material. The precise molds are also produced by multi-cavity such as four-cavity ...

- Lubrication Bottle MoldThe lubricant bottle molds are made by numerical CNC machine and designed by experienced engineer. According to the volume of the lubrication ...

- Toy MoldThe toy mold is designed by experienced engineer and used to produce the toys for children. We adopt numerical CNC machine to make the blow ...

- Cleaning Stuff Bottle MoldThe plastic bottle molds are made by multi-cavity such as 2-cavity, 4- cavity and 6-cavity in accordance with the volume of bottle. Our PET bottle precise molds...

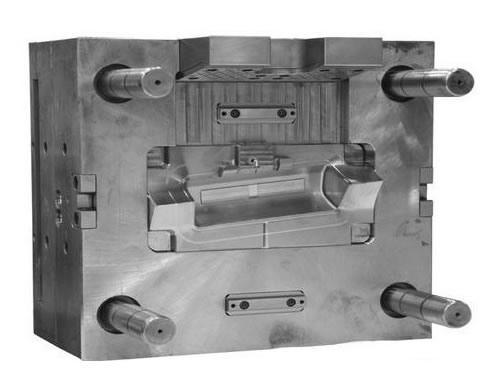

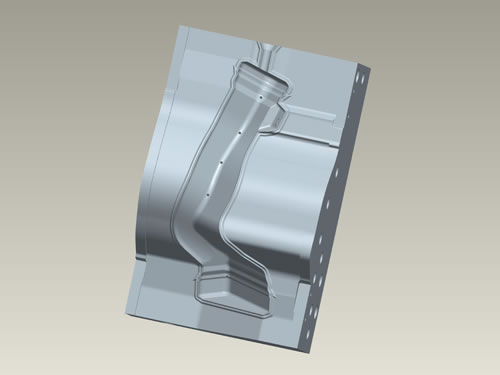

- Auto Parts MoldThe auto parts mold can be divided into various types, such as bumper mold, control panel mould, shock absorber mold, inner trim mould ...

- Chemical Barrel MoldThe chemical barrel molds are manufactured by numerical CNC machine. They are designed by our experienced engineers ...

Precise mold is a tool used to make the materials in specific shape and size by means of injection, blow molding, extrusion, die-casting, stamping and stretching. Leshan precision injection molding equipment and our blow molding machine can complement each other, which will promote better production quality and higher economic benefit.

We possess 20 sets of numerical CNC equipment and experienced skilled technicians to produce the plastic precise mold. Our precision injection molding could be manufactured by multi-cavity in order to increase the production output.