- 75K2X6.5D-A Extrusion Blow Molding Machine1.This blow molding equipment has six die head, double station and single layer with high production output.

2.This extrusion blow moulding machine is suitable for manufacturing milk bottle, glue bottle and drug bottle

3.The maximum blow volume of this injection blow molding machine is 300ml, PE, PP and PS materials can be used ...

- 75K2X1.10D Extrusion Blow Molding Machine1.This blow molding equipment owns single die head, double station and single layer extrusion. It also can be equipped with double die head, four die head, multi-layer extrusion and view stripe

2.The extrusion blow moulding machine is used for the production of 4-5L lubrication bottle, 4-5L cleaning stuff bottle, toy and auto parts ...

- 65K2X1.5D Automatic Blow Molding Machine1.65K2X1.5D automatic blow moulding machine adopts single die head, double station and single layer extrusion. It also can be equipped with double die head, four die head, multi-layer extrusion and view stripe.

2.The automatic blow molding machines are suitable for the production of 4L lubrication bottle, 4L cleaning stuff bottle, toy and auto parts ...

- 55K2X1.2D Bottle Blow Molding Machine1. 55K2X1.2D blow molding equipment is configured with single die head, double station and single layer extrusion. Double die head, four die head, multi-layer extrusion and view stripe are also available.

2. The PET bottle blow moulding machine is suitable for the production of toy, shampoo bottle and cosmetic bottle ...

- 45K2X1.2D Plastic Blow Molding Machine1. This plastic bottle making machine owns single die head, double station and single layer

2. 45K2X1.2D plastic blow moulding machine can be used for the production of toy, shampoo bottle and cosmetic bottle

3. The maximum blow volume is 2L. PE, PP, PS, PC and PVC can be used as the raw materials ...

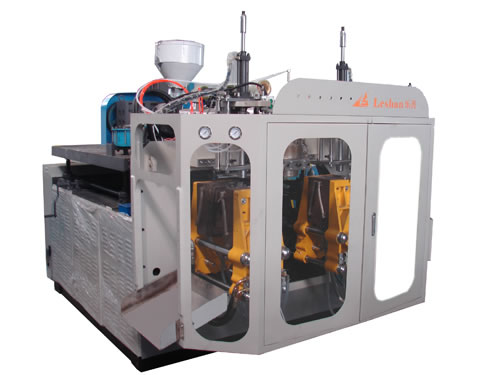

K Series Blow Molding Machine

Description

K series blow moulding machine is used for the production of hollow plastic products under 10L of PE, PP, EVA, ABS, PVC, K material, TPU, BARES, Nylon and other materials. The main difference between U series is that this machine adopts tie bar clamping system. They are easy to manipulate and fix up. Passion control system and auto-deflasher system also can be mounted on K series blow molding equipment. The main features of this model are low energy consumption, raw material-saving, labor-saving and high production rate.

Applications

This blow moulding machine can be used for dairy, food, beverage, medical, cosmetic, personal care, lubrication oil containers, chemical and industrial applications.

Components of K Series Blow Molding Machine

1. All component parts are produced by CNC machine for the purpose of ensuring the precision

2. K series blow molding equipment uses tie bar clamping system, it is also suitable for extending vertical size mold

Properties of K Series Blow Moulding Machine

1. The average energy consumption is lower than the market average of 10%-15%

2. This extrusion blow molding machine has high automation

3. This blow molding equipment can be configured with telemaintenance (WIFI and 3G) control system

4. The blow moulding machines utilize advanced technology to process components which has high precision and quality

Technique Introduction

1.Tie Bar Clamping System

For standard applications, there is no better way than the well proven tie bar clamping system to transfer the forces directly to the middle of the back platen and convert the same force to the front by four tie bars and one alignment rod. This system has a unique way for re-adjusting the deflection as well as the platen parallelism. This open top and side design also offers the fastest and easy mould change.

2. Single & Multiple Extrusion Heads

The single and multiple extrusion heads can be designed with side feed and center feed. Each head is a single head matched to a manifold which splits the stream of melt into the proper number of channels. The quantity of flow in each channel is controlled by an adjusting screw. All heads can be optionally configured with an electronically controlled parison thickness programmer.

3. Co-Extrusion Heads

The co-extrusion heads feature in compact, reliable and excellent functional capability. They allow accurate control of distribution and thickness in each layer, because this is the most important part in the production of multi-layer containers.

4. Automatic Finishing

For post-cooling, it allows a significant increase of productivity by cooling the blow moulding machine in a holding mask before the de-flashing process.

For auto-deflashing, we offer 3 types of de-flashing systems including in-line hydraulic/pneumatic punching or in-line rotary cutting, and outside stand alone deflashing unit. All processes can be finished within the molding area.

5. Extruder

Extruder drives can be connected with a hydraulic motor or inverter-controlled electric motor. The speed of the screw can be adjusted smoothly from the front operating panel. Each heating zone of the extruder is dominated individually and is usually supplied with a cooling fan to control the heating parameters steadily.

The screws are available with an effective 24D length. The mixing tip and shearing zone can be individually optional. The screws are produced by special material and treatment for durability and longevity.

6. Hydraulic System

The hydraulic components of the blow moulding machine are mainly provided by the world famous brands, such as Bosch Rexroth and Yuken. We have cooperated with these suppliers in developing a new cost-efficient hydraulic system. These suppliers offer worldwide guarantee for our users to get the fastest possible response about spare parts and service no matter where in the world.

Maintenance

We provide one year warranty and all-life services for our automatic blow moulding machine. We can send engineers to freely install the machine for domestic customers, while the oversea customers may pay travel expense. Accessories are free replacement for one year except for the easily damaged parts.

Note

Stable blowing air, low temperature cooling water and continuous electricity supply are required

Packaging and Transportation

The blow molding equipment will be packed with film seal

Founded in August 1995, Lanteky® Machine is a professional manufacturer and supplier of blow moulding machine in China. We offer various K series machines, such as 75K2X6.5D-A extrusion blow molding machine, 75K2X1.10D type blow molding equipment, 65K2X1.5D automatic blow molding machine, 55K2X1.2D bottle making machine and 45K2X1.2D plastic blow molding machine. We manufacture our products according to the certificate of ISO9001:2008 quality management system and national measurement system.