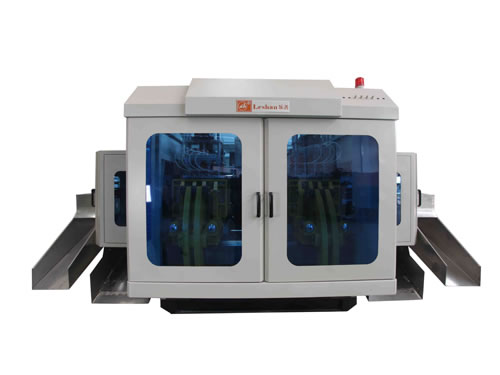

Injection Blow Molding Machine

Description

The injection blow molding machine utilizes imported pentahedral gantry processing center to produce clamping surface in one step. The series blow moulding machine is mainly used to make hollow plastic products with PE, PP, EVA, PVC, nylon and other materials.

All components are made by micro-level CNC machine. This injection blow molding machine uses imported servo motor drive to control preform loading, mold opening and closing. This blow moulding machine has automatic deflasher system.

Features of Injection Blow Molding Machine

1. The die head with high isolation design makes three kinds of melted materials separate with each other before forming parision, so it can ensure the uniform layers and the purity of the finished products

2. The inverter adjusts the speed of the three extruders, and screw speed can be set easily. Therefore, this injection blow molding machine is convenient to control and energy saving

3. The blow moulding machine offers superior extruding ability and double plasticizing effect

4. The series injection blowing machines adopt six position adjustable blowing pin for mold debugging and the improvement of the generality of the machinery

5. Double pump and proportional flow valve can be mounted on this injection blow molding machine for decreasing the power consumption

6. The average energy consumption is lower than the market average of 10%-15%

7. This blow moulding machine can be configured with telemaintenance control system

8. The automatic injection blow molding machine features in stable and easy operation, compact size, high performance as well as highly durable and reliable

Maintenance

We offer one year warranty for our injection blow molding machine. We also can offer free installation for domestic market, and chargeable debugging for oversea market. The equipment parts are free replacement for one year except for the rapid wear parts.

Note

Stable blowing air, low temperature cooling water and continuous electricity supply are requied when the blow moulding machinery is operating

Packaging and Transportation

The injection blow molding machine can be packed and transported with film seal

As a professional blow moulding machine manufacturer, Leshan Machinery offers stable and innovative injection blow molding machine, bottle blow molding machine, extrusion blow molding machine as well as large-scale blow molding machinery and high precise mould. We own powerful comprehensive strength such as strong R&D power, production capacity, marketing ability as well as technical support. Our injection blow molding machines are popular in Malaysia, Indonesia, Nigeria Mexico, Egypt, Dubai, Algeria, Australia, New Zealand, Chile, Mali, Russia, Philippians, Singapore, Vietnam, India and Costa Rica.

- 75U2X1.10F Extrusion Blow Molding Machine75U2X1.10F extrusion blow moulding machines are designed to produce various kinds of containers, such as cosmetic bottle, lubrication bottle, cleaning stuff bottle, toy and auto parts. Combined with in-mold labeling machines, the injection blow molding machines help to eliminate second processing procedure and achieve fully automatic operations from PC material feeding to final product labeling...