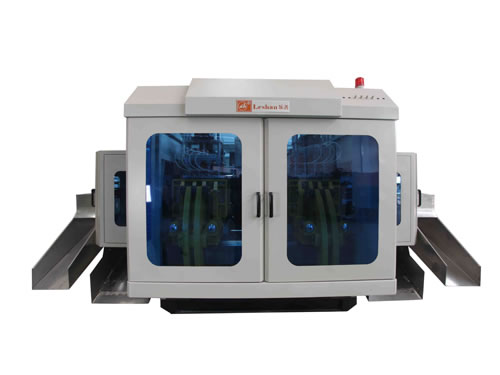

75U2X1.10F Extrusion Blow Molding Machine

Description

75U2X1.10F extrusion blow moulding machines are designed to produce various kinds of containers, such as cosmetic bottle, lubrication bottle, cleaning stuff bottle, toy and auto parts. Combined with in-mold labeling machines, the bottle blowing equipment helps to eliminate second processing procedure and achieve fully automatic operations from PC material feeding to final product labeling.

Features of 75U2X1.10F Extrusion Blow Moulding Machine

1. This type owns single die head, double stations and single layer, and could be configured with double die head, four die head, multi-layer and view stripe

2. With scissors toggle clamping system and high rigidity mold clamping, clamping force is larger than before

3. The extrusion blow moulding machines are suitable for production of 4-5L lubrication bottle, 4-5 cleaning stuff bottle, toy and auto parts.

4. Matching with the double pump and proportional flow valve, the bottle blowing equipment has capacity to reduce the power consumption

5. Automatic lubrication system, thickness control system and auto-deflasher device as well as telemaintenance system are available

6. The screw diameter is 75mm and the maximum blow volume is 10L

7. PE, PP, PS, PC, PVC can be used as raw materials

8. High accuracy linear guide rail is configured to keep fast moving speed and stable production

Components of Extrusion Blow Moulding Machine

1. All component parts are supplied by CNC machine in order to keep the precision

2. The hydraulic pump, pneumatic and electrical parts are imported from the foreign famous brand

3. The extrusion blow moulding machine is equipped with support bracket and linear guide rail in order to guarantee stable and higher moving speed

4. The equalize mold clamping and toggle scissors make the clamping force stronger

5. The bottle blowing equipment can adopt multi-die heads, thickness control system and auto-deflasher. Therefore, this equipment offers high production output with low material and ensure the safety of the workers

Parameters of 75U2X1.10F Extrusion Blow Molding Machine

| Category | / | Single Layer | |||

| Mold | / | 75U×1.10F | 75U2×2.10F | 75U2×4.10F | |

| Max Volume Blown | (L) | 10 | 2.5 | 1 | |

| Applied Material | / | PE,PP,PS,PC | PE,PP,PS | PE,PP,PS | |

| No. of Die Head | / | 1 | 2 | 4 | |

| Central Distance | (mm) | 120,200 | 85,100 | ||

| No. of Station | / | 2 | 2 | 2 | |

| Screw Dia | (mm) | 75 | |||

| L/D Ratio | / | 24 | |||

| Screw Rotating Speed | (rpm) | 20~63/(20~83) | |||

| Max Plasticizing Capacity | (kg/h) | 90/(120) | |||

| Extruding Motor Power | (kW) | 22/(30) | |||

| Oil Pump Motor Power | (kW) | 11 | |||

| Barrel Zone | / | 3 | |||

| Barrel Heating Power | (kW) | 12.5/(13.5) | |||

| Head Heating Zone | / | 2 | 5 | 9 | |

| Head Heating Power | (kW) | 7 | 8 | 7 | |

| Transformer Power of Hot Cutter | (kW) | 2 | |||

| Total Power | (kW) | 54.5/63.5 | 55.5/64.5 | 54.5/63.5 | |

| Min Clamping Distance of Mold | (mm) | 230 | |||

| Mold Stroke | (mm) | 350 | |||

| Max Size of Mold | (mm,W×H) | 640×430 | |||

| Clamping Force | (kN) | 125 | |||

| Net Weight | (kg) | 9000 | |||

| Dimension of Machine | (m,L×H×W) | 4.34×2.6×3.15(2.2) | |||

| Pressure of Hydraulic System | Mpa | 14 | 14 | 14 | |

| Pressure of Pneumatic System | Mpa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | |

| Pressure of Cooling System | Mpa | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | |

| Air Consumption | m3/hr | 5 | 5 | 5 | |

Maintenance

We provide one year warranty and all-life services for our extrusion blow moulding machine. We can send engineers to freely install the machine for domestic customers, while the oversea customers may pay travel expense. Accessories are free replacement for one year except for the easily damaged parts.

Note

Stable blowing air, low temperature cooling water and continuous electricity supply are required

Packaging and Transportation

The bottle blowing equipment will be packed with film seal

We are professional extrusion blow moulding machine manufacturer and supplier in China. We can provide the blow molding machine according to your requirements. Bedsides 75U2X1.10F extrusion bottle blowing machine, we also supply 85U2X8.5G extrusion blow molding machine, 65U2X6.2G automatic blow molding machine and 65U2X1.5F bottle blow molding machine. Adopting advanced technology, the average energy consumption of our extrusion blow moulding machine is lower than the market average of 10%-15%. This bottle blowing equipment also can be modified through WIFI and 3G.

- 65U2X6.2G Automatic Blow Molding Machine65U2X6.2G automatic blow molding machine with high production output can be used for producing milk bottle, glue bottle and drug bottle, especially for the hollow plastic products with the volume from 30L to 100L. This blowing machine is applicable to dairy, food, beverage, medical, cosmetic, personal care, lubrication oil containers, chemical and industrial applications...