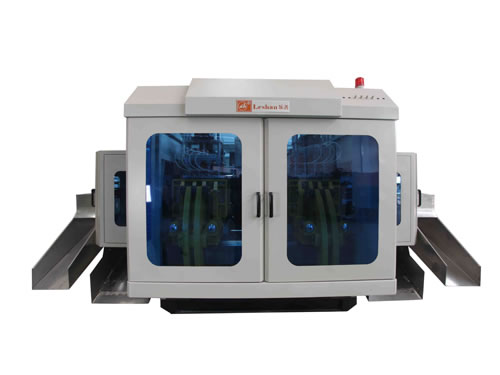

Blow Molding Equipment

Description

Blow molding equipment, configured with hydraulic vertical blowing pin and manual centralized lubrication system, has faulty alarm and self-error diagnosis functions. The computer operation screen can monitor the action status, and can automatically calculate the output and realize automatic reset.

This blow molding equipment applies to the production of PE, PP, EVA, ABS, PVC, K material, TPU, BARES, nylon and other materials of hollow plastic products, such as blow molding barrels, five gallons of purified water buckets, cans, bags, boxes and air pipe.

Features of Blow Moulding Equipment

1. The blow molding machines adopt high rigidity clamping frame to provide sufficient clamping force for the molds

2. We adopt imported pentahedral gantry processing center to machine all clamping surface in one step

3. The blow molding equipment utilizes micron-level CNC machine to produce its components

4. Deep crystal surface treatment within the die head, our plastic blow molding machine has no dead ends

5. It is easy to refuel materials, change color, and remove slag and clean die head

6. This blow moulding equipment adopts new platform type head rising design, which can separate the lift platform from the rising one

7. New type fully computer control lubrication system is used to maintain the blow molding equipment

8. Our blow moulding machine can be equipped with conveyor belt and feeding machine in order to accomplish high automatic production

9. This automatic blow molding machine is designed and manufactured in accordance with the German standards of same models

10. The blow molding equipment can be also configured with automatic lubrication system and telemaintenance system

11. Other characteristics of this blow moulding equipment are stable and easy operation, high performance, low power consumption as well as durable and reliable

12. The super size blowing machine adopts light curtain safety protection system to ensure the personal safety of operating personnel

Maintenance

One year warranty is offered for our blow molding equipment. We can provide free installation for domestic market, chargeable debugging in oversea market. The equipment parts are free replacement for one year except for the easily damaged parts.

We are professional manufacturer and supplier of blow molding equipment in China. Our products are exported to Malaysia, Indonesia, Nigeria Mexico, Egypt, Dubai, Algeria, Australia, New Zealand, Chile, Mali, Russia, Philippians, Singapore, Vietnam, India and Costa Rica. We adopt international standards and the ISO9001:2012 quality management system to manufacture our blow moulding equipment. We utilize statistical indicators and quota quantitative index to control the production speed and quality. If you are interested in our blow molding equipment, please feel free to contact us.

- 75U2X1.10F Extrusion Blow Molding Machine75U2X1.10F extrusion blow moulding machines are designed to produce various kinds of containers, such as cosmetic bottle, lubrication bottle, cleaning stuff bottle, toy and auto parts. Combined with in-mold labeling machines, the blow molding equipment helps to eliminate second processing procedure and achieve fully automatic operations from PC material feeding to final product labeling...