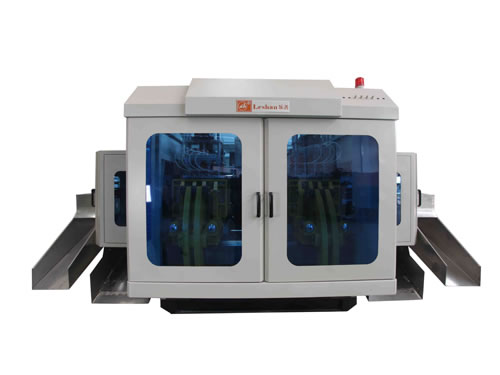

Blow Moulding Machine

Description

The blow moulding machine is used to blow and produce the containers with different volume capacity such as 0.5L, 5L and 30L. The high reliability, excellent efficiency and high automation can meet the various demands of the users.

The extrusion blow molding machine can process a variety of materials, including PET, PP, PVC, EVA, TPU and other materials. The blow moulding machine is applicable to the production of beverage packaging, cosmetic containers, pesticide bottle, mineral water bottle, cans, bags and other hollow plastic products.

Features of Blow Moulding Machine

1. The production output can reach 4000-5000Pcs/h

2. Compared with other machine, this extrusion blow molding machine can save 30% energy

3. This blow moulding machine adopts imported famous components, such as FESTO, SMC, PARKER, OMRON, SIEMENS, CONTRINEX and PHILIPS

4. The extrusion platform is equipped with hydraulic lifting system

5. This blow molding machine only needs seven seconds to accomplish the dry cycle

6. Deep crystal surface treatment within the die head, the extrusion blow molding machine has curved runner and no dead angle

7. It is convenient for this blow moulding machine to change the material and color, to remove slag and clean the die head. Tube symmetrical parts of the wall thickness are very uniform

8. The users can select divergent die, spiral die or plastic extrusion die in accordance with user preference

9. The clamping plate is made of ductile cast iron, which is stable and durable

10. The blow moulding machine adopts safety door to ensure the personal security of the workers, the machine is at work when the door closed and stops while door opened

11. In order to facilitate recycling the material, this extrusion blow molding machine offer optional functions like automatic hydraulic filter device, down blow pin, parison thickness controller, scraper and deflaser

12. The demoulding device and manipulator can be used according to the requirement of the users

Leshan Machinery devotes itself to blow moulding machine in China. Till now, we have Pentahedron gantry machining center, four-axis vertical machining center, numerically controlled lathe, numerical controlled bending machine, numerical controlled cutting machine and other specialized equipment. Through the years of continuous innovation, we have transformed the patented technology into application. We adopt international standards and the ISO9001:2012 quality management system to manufacture our blow moulding machine.

- 75U2X1.10F Extrusion Blow Molding Machine75U2X1.10F extrusion blow moulding machines are designed to produce various kinds of containers, such as cosmetic bottle, lubrication bottle, cleaning stuff bottle, toy and auto parts. Combined with in-mold labeling machines, the extrusion blow molding machines help to eliminate second processing procedure and achieve fully automatic operations from PC material feeding to final product labeling...